Conductor Configuration

Stranded conductors are composed of un-insulated strands of wire twisted together. The advantages of stranded conductor over a single strand of equal cross-section are increased flexibility and flex-fatigue life. Stranded conductor can be manufactured in a variety of configurations, the most common being concentric, bunched and ropes.

Concentric

When the term “concentric stranding” is used, it refers to the definition of the word “concentric”, which is having a “common center”. Concentric conductor may be defined as:

“A central wire (strand) surrounded by one or more layers of helically laid wires in a geometric pattern.” The geometric pattern requires that concentric constructions can only be produced with 7, 19, 37, 61, (etc.) strands or members, following the pattern that each successive layer has 6 more strands than the layer below it. In all types of concentric constructions, the geometric pattern of the strands is consistent for the entire length of the conductor. That is, the central strand, and the strands in each layer remain in their respective positions from the beginning to the end of its length. The main advantage of concentric constructions is the close/tight diameter tolerances that can be maintained on the conductor. Concentric constructions have very smooth uniform surfaces that are suited for thin wall insulation in high performance applications.

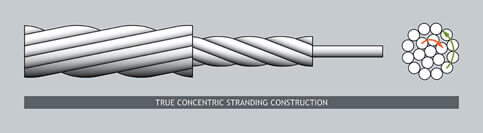

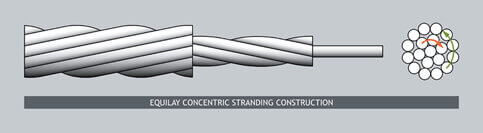

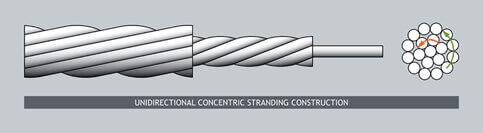

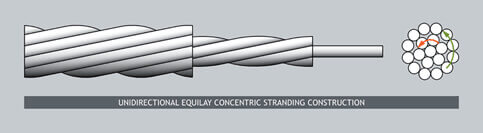

Concentric Stranding

There are four common types of concentric constructions manufactured for the high performance wire and cable industry. Although there are 4 distinct types, the industry normally refers to “Concentric” as “True Concentric” and will use the terms interchangeably. The other types are referenced as noted.

Concentric or True Concentric characterized by a central wire surrounded by one or more layers of helically laid wires in a geometric pattern, with alternately reversed lay direction and increasing lay length.

Equilay or Equilay Concentric characterized by a central wire surrounded by one or more layers of helically laid wires in a geometric pattern, with alternately reversed lay direction and the same lay length.

Unidirectional or Unidirectional Concentric characterized by a central wire surrounded by one or more layers of helically laid wires in a geometric pattern, with the same lay direction and an increasing lay length.

Unilay or Unidirectional Equilay Concentric characterized by a central wire surrounded by one or more layers of helically laid wires in a geometric pattern, with the same lay direction and the same lay length.

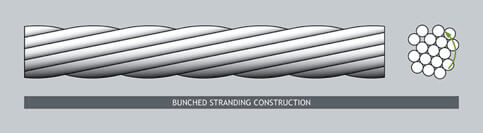

Bunched Stranding

Bunch strand wire contains any number of strands in random pattern. Twisted in one operation, all strands have the same lay direction and same lay length, however, the result is a rougher surface and lower dimensional tolerance than the concentric constructions. The number of strands is determined by the size of the individual strands and the total cross-sectional area required.

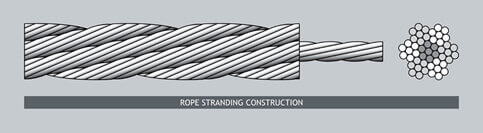

Rope Lay Stranding

Wire constructions consist of single strands assembled together into concentric or bunched configurations. Rope constructions consist of concentric or bunched members stranded together into the final concentric or bunched configuration.

Rope stranding has the advantage of increasing flexibility by using a larger number of finer strands while maintaining a tighter diameter tolerance than a simple bunched construction. Ropes are more evident in the larger AWG sizes, such as 8 AWG and larger, but there also many applications that require the flexibility of rope constructions in the smaller gauges. Constructions vary and can contain hundreds or thousands of strands.

SPC PRODUCTS

Survey No 212, B/h. Lalit Ware House,

Nr. Cozy Hotel, Narol-Sarkhej Highway,

Narol, Ahmedabad-382 405.

[Gujarat] INDIA.

MOBILE : +91 82005 10421

+91 93746 51945